Phosphor Screens

Phosphor Coatings for Electron and X-Ray Detection

Phosphor Screens

Introduction

Fluent Wave provides a variety of phosphor coatings for electron and X-ray detection. Products are designed in close cooperation with our customers. Production is done in a state-of-the-art cleanroom environment.

Technology

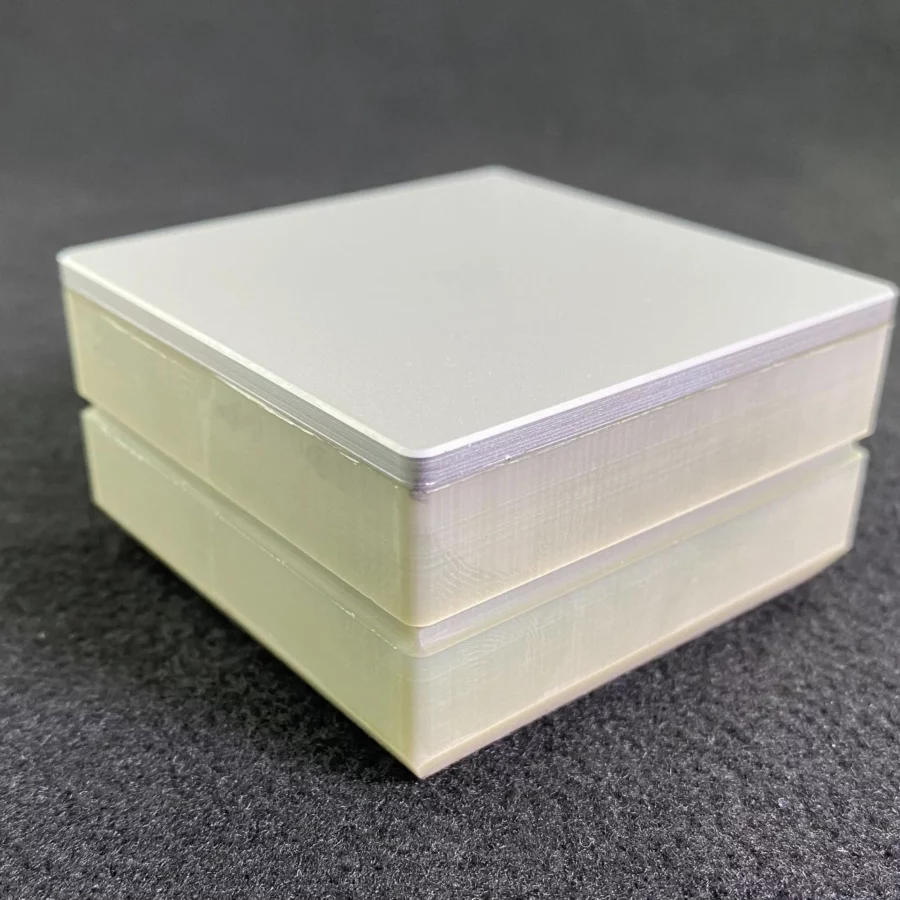

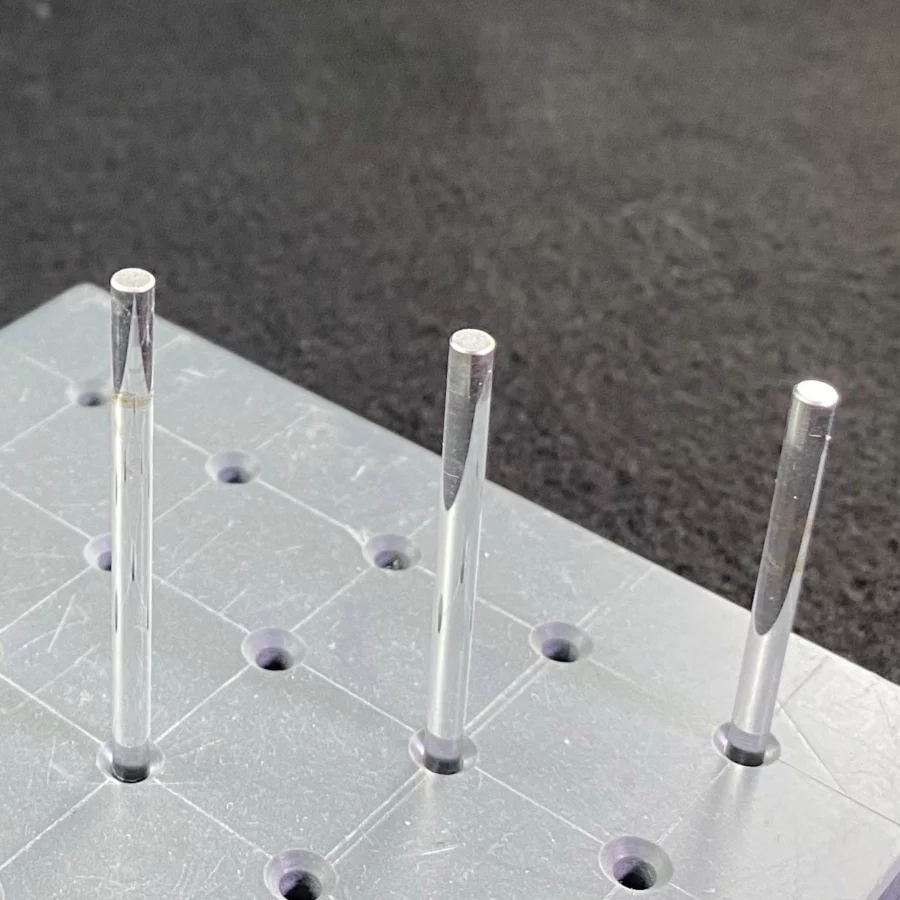

Phosphor screens are produced by sedimentation technology which results in very high-density layers. All process steps take place in a cleanroom environment (Class 1000) to guarantee optimum quality. Standard available substrates are aluminum, stainless steel, glass, and fiber optic plates. Substrates sizes vary from 3 mm round-up to 200 x 200 mm.

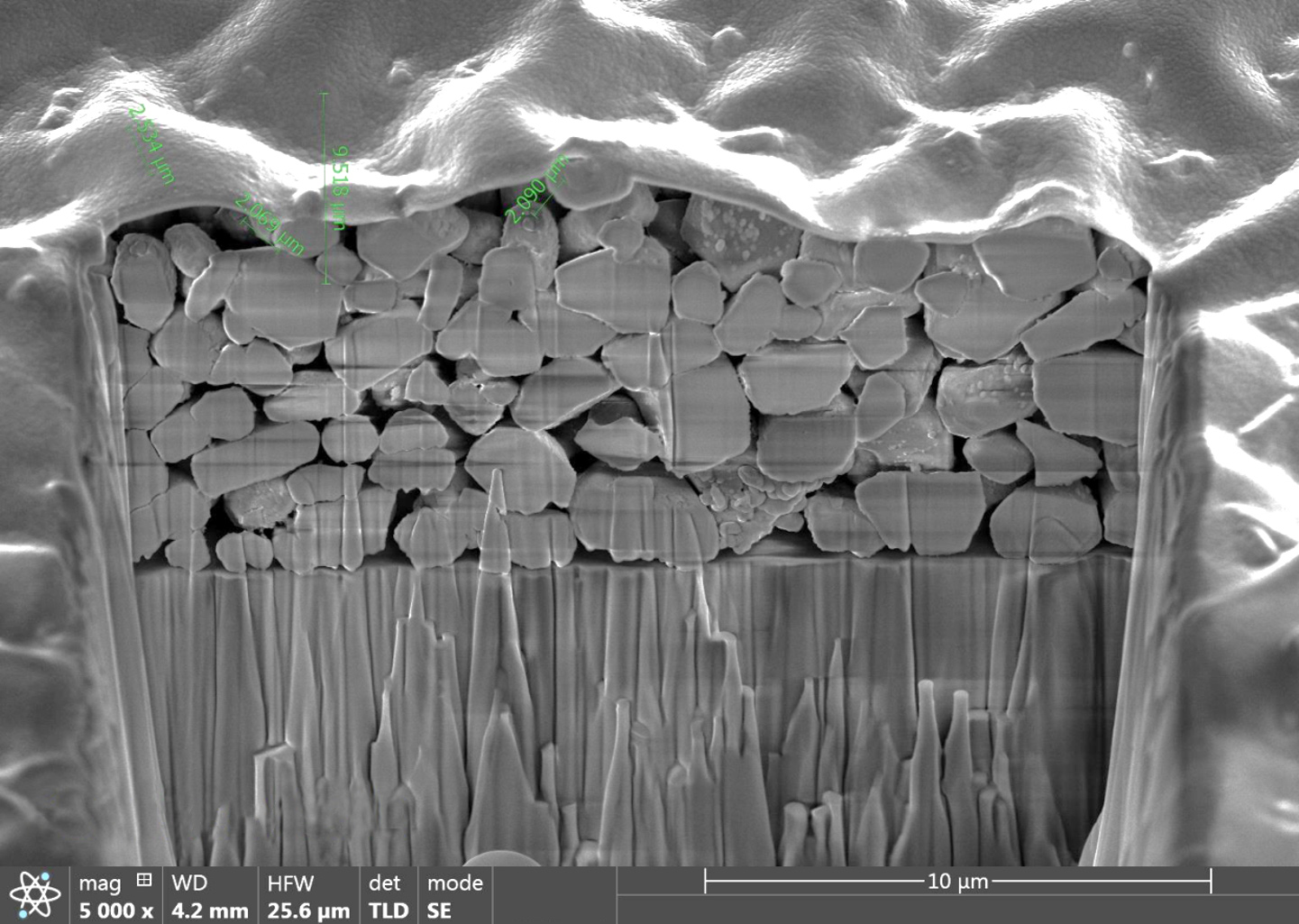

The most commonly used phosphor types are P22, P43, P47 (other types are possible). Layer thicknesses vary from 5 to 200 µm depending on customer application. Phosphor particle sizes typically range from 1 to 25 µm. Several top coatings can be applied, e.g. aluminum and parylene.

Inspection

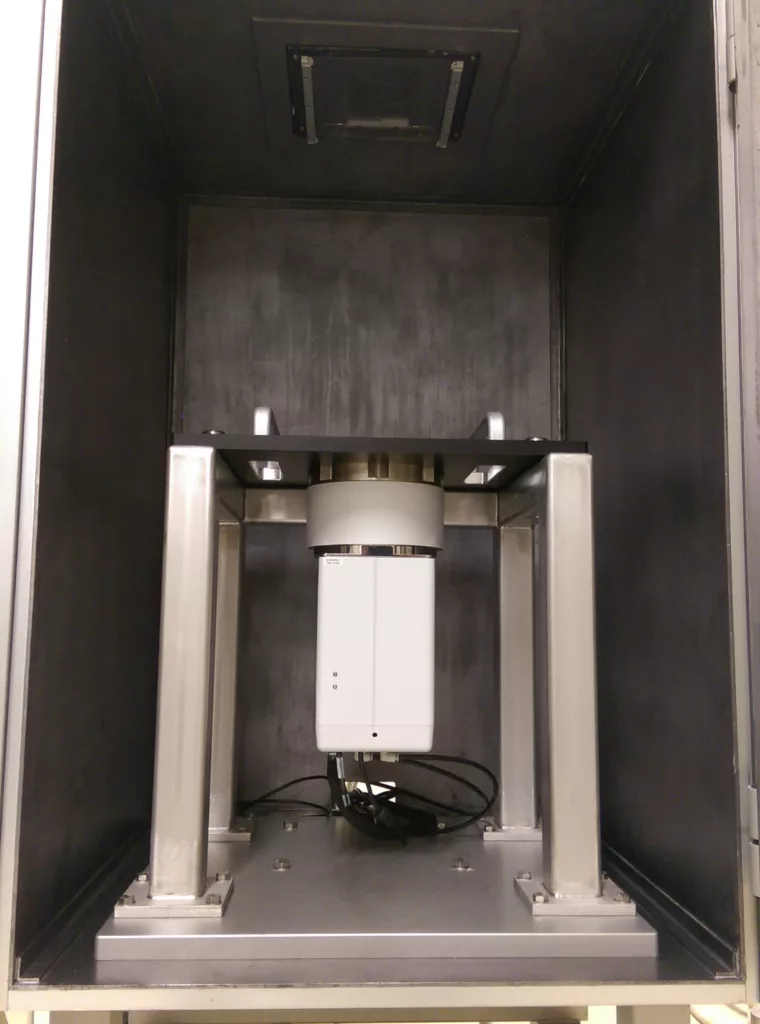

In-process and outgoing inspection is done with a wide variety of techniques e.g. microscope and X-ray screening.

Products can be tested on:

- Conversion efficiency

- Light output uniformity

- Modulation transfer function (MTF)

- Detective quantum efficiency (DQE)

- Afterglow and blemishes.

X-Ray inspection:

Scanning electron microscope:

Applications

Fluent wave phosphor screens are used in a wide variety of applications e.g.

- Scanning electron microscopy (SEM)

- Transmission electron microscopy (TEM)

- Dental imaging